Humanoid Robots for Shipyards

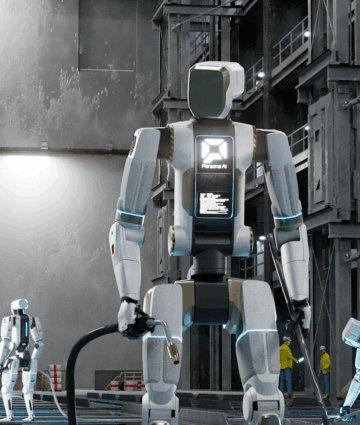

Humanoid robots for shipyards will transform global shipbuilding. Persona AI is pioneering this shift with industrial humanoids built for heavy maritime work.

Humanoid robots for shipyards will transform global shipbuilding. Persona AI is pioneering this shift with industrial humanoids built for heavy maritime work.

Fixed robotic arms have been effective in manufacturing environments with predictable workflows, but shipyards are far more complex. These arms cannot climb scaffolding, crawl into confined compartments, or adapt when conditions change. Shipbuilding requires dexterity, balance, and adaptability that static robotic systems simply cannot provide.

Exoskeletons have shown promise in reducing worker fatigue and enhancing strength for specific tasks, but they do not address the fundamental issue: there are not enough workers available to begin with. Even if every shipyard worker were equipped with an exoskeleton, the shrinking labor supply would still leave critical gaps in production.

Unlike highly automated factories, shipyards cannot afford to tear down and rebuild their processes to fit robotic infrastructure. They require solutions that seamlessly integrate into existing workflows – climbing ladders, holding tools, navigating uneven surfaces. Humanoid robots, by design, will be the first form of automation that truly adapts to human-centric environments rather than forcing costly overhauls.

Shipbuilding has one of the highest attrition rates in heavy industry: The U.S. Navy reports ~30% turnover in skilled trades.

South Korea and Japan already report multi year backlogs on commercial ship orders due to labor shortages.

By 2030, over 40% of the skilled U.S. shipyard workforce will retire, while fewer young workers are entering the trade.

Shipyards are among the most dangerous industrial environments in the world. Workers face hazards ranging from working at height on scaffolding to exposure to welding fumes and the risks of confined spaces deep within ship hulls. As global regulations tighten and safety expectations rise, shipyards will be forced to seek new solutions to reduce accidents and liability costs. Humanoid robots will play a critical role by performing the most hazardous tasks, allowing humans to step back from the front lines of danger.

Demand for naval and commercial ships is rising rapidly, driven by defense modernization and expanding trade. Traditional labor models will not scale to meet this need.

The International Maritime Organization (IMO) projects that maritime trade will grow by 70% by 2050, putting enormous strain on shipbuilding capacity .

The U.S. Navy’s FY2025 budget requests over $33 billion for shipbuilding, one of the largest in its history .

China has launched more naval ships in the past decade than the U.S., India, and Japan combined, signaling a global arms race in shipbuilding .

Our team has led some of the world’s most notable robotics projects. We’ve each spent decades taking robots from controlled labs into harsh environments like space and the depths of the sea – and we’re not done moving the needle yet.

Humanoid robots will fit directly into existing shipyard workflows, making adoption easier and faster than previous waves of robotic solutions. They will not require costly infrastructure changes; instead, they will operate within the same environments as skilled tradespeople, enabling faster integration and higher ROI.

Humanoids will work with the same tools and navigate the same environments that shipyard workers already do. This allows shipyards to deploy them without reengineering processes, accelerating time to value.

As shipbuilding accelerates globally, humanoid robots will not only fill labor gaps but also redefine efficiency and safety standards. By combining dexterity with rugged durability, Persona AI’s humanoids will set a new benchmark for maritime automation.

Shipyards are among the toughest industrial workplaces, with heat, sparks, saltwater, and heavy equipment in constant use. Persona’s humanoid robots will be purpose-built to withstand these conditions, ensuring reliability where traditional robotics would fail.

Persona AI is advancing the next generation of humanoid robots for shipyards, energy, construction, and defense. We’re looking for exceptional engineers, builders, and innovators who will help shape how humanoids perform skilled industrial work across the world.

If you have experience in robotics, mechanical design, embedded systems, or industrial operations, or if you’re passionate about redefining what machines can do; we’d like to hear from you.

"*" indicates required fields

Optional Eyebrow Headline

Shipyards will face a hard economic shift: injury rates in shipyard work remain more than 2× those of construction and general industry, which drives costly downtime and claims. Every medically consulted workplace injury in the U.S. averaged $43,000 in 2023. Reducing human exposure to hazardous welding, confined spaces, and working at height will directly improve margins — this is where humanoids will pay for themselves.

At the same time, demand will rise while skilled labor thins. U.S. welding workforce data projects 320,500 new welding professionals needed by 2029, even as shipbuilding requests remain elevated (the Navy’s FY2025 shipbuilding request totals $32.4B). Humanoid robots will bridge this supply gap without forcing shipyards to redesign processes.

$43,000

Average Cost Per Work Injury

Per-injury cost for a medically-consulted case. Cutting exposure to high-risk shipyard tasks (welding fumes, falls, confined spaces) will compound savings across large yards.

320,500+

Projected Welders Needed by 2029 (U.S.)

Persistent welder shortages will continue even with training pipelines. Humanoid robots will help sustain throughput when human hiring alone cannot.

2x

Shipyard Injury Rate vs General Industry

OSHA notes that shipyard work has an injury accident rate more than twice that of construction and general industry; this presents a direct ROI target for humanoid deployment.